Brambati President Fabrizio Brambati on the importance of sustainability and why innovation and flexibility are key to the company’s success.

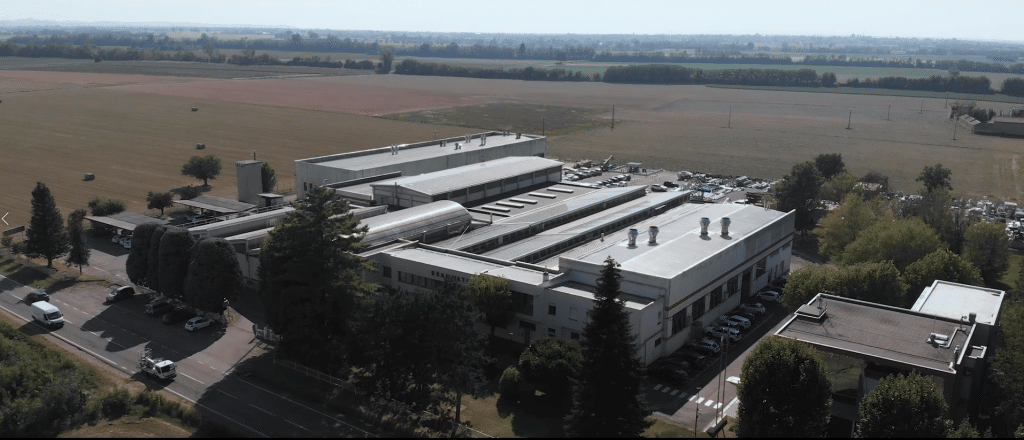

Across the global coffee supply chain, sustainable solutions are identified as a major focus of concern and urgency to reduce the industry’s carbon footprint. The push for a greener future has resulted in factories implementing solar power, using recycled products, and driving social and economic sustainable practices. However, when it comes to roaster manufacturing, Brambati S.p.A Owners Andrea and Fabrizio Brambati are determined to operate the business without waste.

“The company has heavily invested in research and development over the past couple of years to improve energy efficiency in the workplace,” says company CEO Fabrizio Brambati.

This includes installing a large-scale solar system, capable of producing 200 kilowatts of power and producing 60 per cent of Brambati’s electrical needs. The company has replaced old lighting systems with new LED lights, removing its diesel heating system with the installation of heat pumps and high efficiency condensing boilers. It continues to monitor the energy and water consumption of the factory, and fuel consumption of its transport fleet.

Brambati says he’s noticed concrete improvements, and is committed to controlling reduced emissions in the machinery.

“To reduce indirect emissions, we reduce consumption by installing more efficient components or even eliminating some components,” he says.

“For primary emissions, we use a low NOx burner and high efficiency catalytic systems.”

In its roasting equipment, Brambati supplies an Eco afterburner that can be fitted to each of its roasters as well as its most popular styles of roaster, the KAR and BR series in Eco models.

This aims to reduce emissions, power, and gas consumption, and increase efficiency.

“Our machines are made with Ecodesign, in accordance with ISO 14006 [environmental management systems],” says Brambati.

At Brambati, sustainable practices don’t just apply to the manufacturing of equipment but are integrated in the company’s 360-degree sustainable philosophy.

“We are completely self-sufficient. We use solar panels to harness energy to power our facility and have implemented many controls to ensure there is no waste,” Brambati says.

“We started from the measurement of consumption and waste and then, during the redesign [of our machinery], we have reduced the number of components used and the working waste,” says Brambati.

Brambati’s commitment to sustainability earned the company a Gold Certificate in November 2021 from EcoVadis, an independent company that evaluates sustainability and the corporate responsibility in global supply chains.

“At Brambati, we recognise the importance of adopting a sustainable approach for civil society, including local communities, associations and authorities, and we’re working to leave a durable environmental legacy for future generations,” says Brambati.

Francesco Brambati founded the Italian manufacturing business in 1945, originally producing flour mills before it started to manufacture roasting equipment in the 1960s.

For more than 75 years, Brambati has led technological innovations within the industry, with the development of electronic controls in the 1960s and turnkey solutions in the 1970s, to its modern adoption of 3D engineering and design technology.

Brambati’s ability to be flexible and customise its machinery to adapt to its customer’s needs has been a key reason for its success in the market.

“Our clients know that with Brambati equipment, we deliver on quality to maximum efficiency, while limiting power consumption and reducing emissions,” says Brambati.

Another of Brambati’s strengths is its continuous support service to manage any issue that may arise. Everything is handled internally, thanks to Brambati’s team of engineers, rather than relying on external services.

“If a customer ever has a problem, they come straight to us for immediate results, which I think makes a really big difference as it’s not something most companies offer,” Brambati says.

To ensure the safety of its machinery, Brambati says the company is constantly developing and improving its technology.

This includes the development of specialty software in its BR models that allows users to overlap historical curves during the roasting phase, view discrepancies, and verify variations or any drifts in real time.

“Now, the biggest advantage we have is that our machinery can consider and prevent any potential problems, which saves time and expenses of stopping production,” he says.

In addition to its advances in safety, in 2018, Brambati launched the Advanced Food Lab (AFL), a cutting-edge research and development centre which has been recognised with Specialty Coffee Association (SCA) Premier Training Campus certification, a program that highlights facilities that offer a unique educational setting for coffee education.

“This is a great achievement, especially nowadays when specialty coffee is becoming more and more popular,” says Brambati.

The AFL, with its complete pilot plant, was designed to increase the brand’s scientific capabilities so it can continue to push the limits of technological advancements.

It features a laboratory, 3D scanners, dedicated graphics software, and the infrastructure to conduct rigorous testing.

“The AFL is a result of Brambati’s continuous commitment to search for innovation, where theoretical tests and trials are not enough. Instead, there is a need to test, confirm and support results with laboratory analysis,” says Brambati.

He adds that the AFL and its specialised technical division positions Brambati at the forefront of roasting expertise, with its competitive advantage in the flexibility of Brambati’s catalogue.

“Innovation and flexibility are two of the core pillars that this brand is built on. We are constantly seeking to develop our processes and technology,” Brambati says.

“We take pride in our products being adaptable and consistent. Our machines today are suitable for every kind of coffee and are able to obtain results that every professional roaster wants.”

To assist potential buyers make purchasing decisions, Brambati has also embraced digitalisation in the form of webinars and educational online classes based in its AFL, showcasing how to use its machinery.

“Brambati runs 80 per cent of the business out of Italy, so it’s important to us that we allow our customers the possibility to train remotely, and commissioning installation remotely, to guarantee the satisfaction of our customers,” Brambati says.

“It’s been a great advantage over the past couple of years. This ensures we maintain a close connection with our clients, which is very important to us.”

The webinars allow clients to explore Brambati’s latest advancements in roasting technology and automation, and adapt it into their own facility.

“The courses are dedicated to customers that have our machinery and wish to improve their knowledge on how to best use the equipment, to ensure they understand the full capabilities of the machinery. By utilising the machine to its full potential, they can achieve the best results,” says Brambati.

“It’s also a way for us to show new customers the features of the equipment and the advantages of using our products.”

Brambati can organise seminars collectively with the SCA to showcase the technology Brambati offers and how it can best be utilised in daily roasting practices.

“For example, people that want to know how certain coffee behaves in the roasting process or want to create a new recipe can see the equipment in action,” Brambati says.

He adds that further digitalisation and sustainability will continue to be major goals for the company moving forward, as is continuing to explore new trends, advance its technology, and expand its market reach even further.

“Brambati treats its family tradition with respect while also looking to enhance it in an innovative way, in the knowledge that research and development, integration and attention to current issues regarding sustainability are basic to a viable, lasting future.”

For more information, visit www.brambati.it/it/

This article was first published in the January/February 2022 edition of Global Coffee Report. Read more HERE.