Cama Group on embracing Industry 5.0 and rolling out its Machine Enhancement Program to improve the productivity and sustainability of its secondary-packaging machines.

While the first industrial revolution began in the 18th century, according to European researchers we have since advanced through four more iterations as we move into the era of Industry 5.0.

Formally introduced by the European Commission in 2021, the Industry 5.0 paradigm is described by the executive branch of the European Union as “a vision of industry that places the wellbeing of the worker at the centre of the production process and uses new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet”.

More broadly, the concept focuses on humans and machines working together. The idea is that the implementation of collaborative robots will free up people to add value to the customer experience and use their skills to deliver a competitive advantage.

Secondary-packaging machine manufacturer Cama Group is embracing this new era of industry. Its team believe we’re in the middle of a cultural change that redraws the boundaries between humans, machines, and artificial intelligence.

“Our goal is to make sophisticated systems simple according to the Industry 5.0 paradigm, which brings humans and machines closer together through interfaces, contextualised language, and shared goals,” says Head of Research and Development Massimo Monguzzi.

Generating solutions

The use of artificial intelligence (AI) and Generative AI (GenAI) are particular areas of interest for the team. According to Monguzzi, they have potential to improve products, processes, and services.

“From an initial curiosity, AI and GenAI have now become work tools. The first area has been the writing of software code, which is becoming increasingly high level. We are rethinking the approach to programming to automate repetitive operations such as code writing,” he says.

“Delegating code generation to AI allows developers to focus on higher value-added activities. Writing code will be like tightening a screw: a necessary activity, but not strategic.”

Alongside code writing, the team are also using this technology to develop technical documentation such as manuals, technical files, risk analyses, and declarations of conformity, which are usually time-consuming to produce.

“GenAI speeds up the creation of these materials if it is integrated in a data-rich context from which it can learn. Cama has a significant documentary asset made up of thousands of drafted technical files,” says Monguzzi.

“In similar scenarios GenAI proves effective, even if it cannot replace human control, but it increases productivity. It also reduces errors and enables greater standardisation of technical content.”

To optimise its secondary-packaging solutions and make them even more efficient for its customers, Cama’s Research and Development division is producing new algorithms to study machine data in depth and identifying correlations between operating parameters and performance.

“Production efficiency is also correlated with environmental variables. For example, humidity varies according to the seasons and the geographical area. It affects the machinability of materials and the quality of packaging,” Monguzzi says.

“The same goes for temperature, which accelerates the wear of various parts. Knowing the functions of these parameters in depth makes it possible to improve the setting of the machines and prevent potential problems.”

Continual enhancement

These explorative projects run alongside Cama Group’s long-established Machine Enhancement Program, a continuous research and development process that aims to progress the company’s packaging machinery and robotic solutions through the introduction of “cutting-edge technologies”.

According to Sales Group Director Alessandro Rocca, the program has a strong focus on resource savings in terms of materials, energy, time, and space.

“The Machine Enhancement Program currently includes five fully operational systems and two modules in advanced development. It is a scalable platform that can be applied both to new installations and as a retrofit on existing packaging lines,” he says.

“The program improves productivity, reduces waste and energy consumption, and makes packaging more sustainable. Its adoption is fast and delivers tangible benefits in format changeover, process quality, and production continuity.”

The five operational systems that are in use across Cama’s fleet of machinery are: augmented reality, digital twin, automatic format changeover, automatic carton loading, and automatic collaborative palletising. Each is designed to aid the production process for manufacturers and increase the performance of their packaging lines.

The first step of the Machine Enhancement Program is augmented reality, which is now a standard on all new machines and available as a retrofit on most recently installed bases.

Using a tablet to scan QR codes placed on different machine areas, operators can access a digital environment with step-by-step procedures, 3D animations, dedicated checklists, and specific documentation. Replacing traditional operating manuals, the goal is to save time, prevent errors, and simplify daily work.

“Augmented reality guidance makes even the most advanced machines easier to use. Every step is visualised and contextualised, reducing complexity and smoothing the learning curve,” says Rocca.

“Operators learn faster and better in front of the machine in virtual mode, projecting the model onto a table or using virtual reality to train without stopping the line.”

The digital twin feature is used during the initial engineering stage, or whenever the behaviour of the line needs to be analysed with specific product types. It simulates vision systems, picking logics, quality control, and product behaviour along the cycle so design can be completed before actual production starts.

“The added value lies in its ability to predict cycle time, validate product picking, and verify production flow consistency, while also measuring the impact of format variants without building physical prototypes. This shortens timelines and reduces the risk of errors,” Rocca says.

The Cama team have identified human errors and downtime as being the two main weaknesses of packaging lines. To address these issues, they developed the automatic format changeover system.

“The logic is simple: choose the recipe, press a button, and the machine adjusts itself. In daily practice, this means changeover time is at least halved compared to manual operations,” Rocca says.

“Fully automatic format changeover is especially useful where staff turnover is high: teams that change every month do not have to relearn the machine from scratch.”

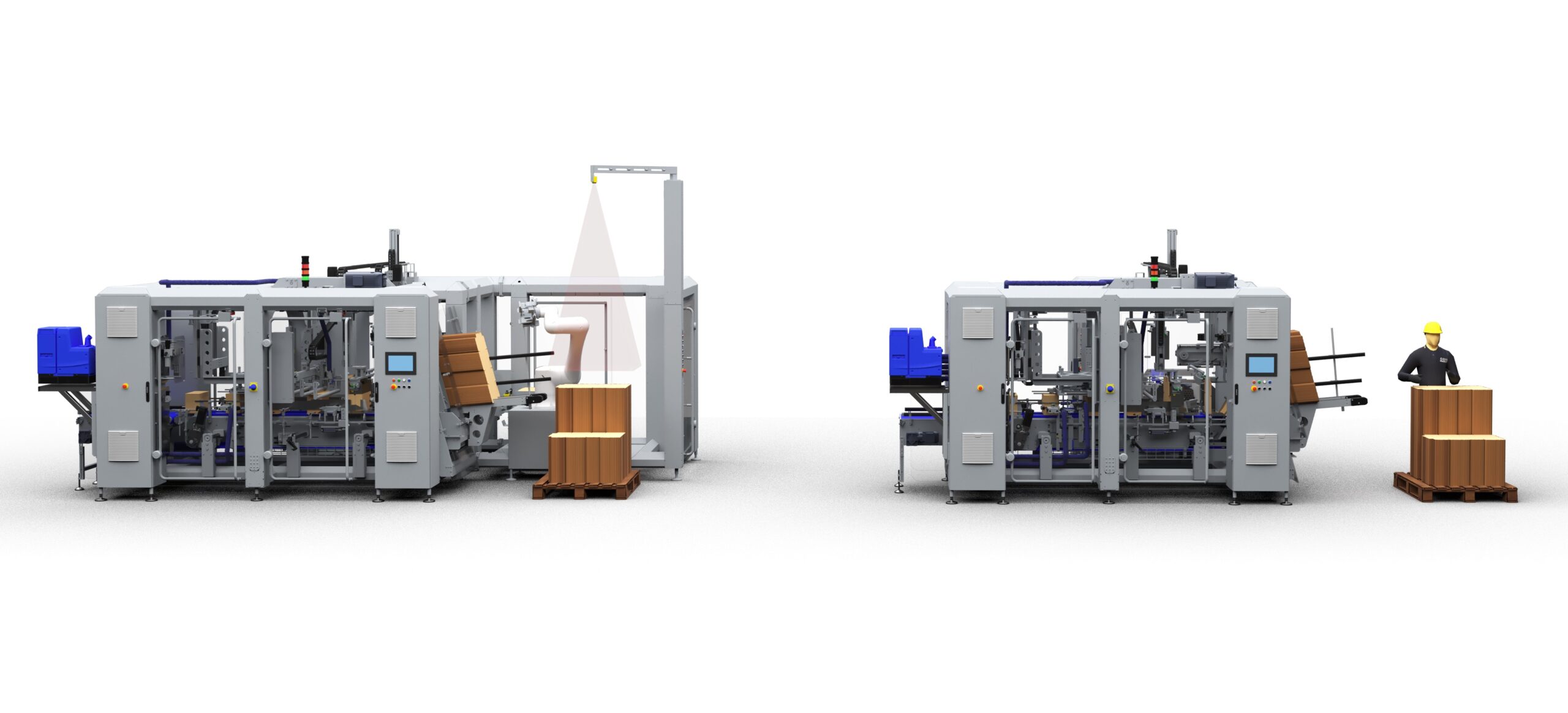

One of the most recent additions to the Machine Enhancement Program is automatic carton loading, which was previewed at Ipack-IMA in May 2025. The system uses collaborative robots to pick the die-cut blanks from the pallet and feed them into the machine’s carton magazine.

“The advantage is felt immediately in production. Feeding the magazine is no longer a bottleneck: the robot keeps the flow constant, reduces micro-stops, makes the cycle stable, and preserves the quality of the cardboard because handling is repeatable and controlled,” says Rocca.

“In parallel with automatic carton loading is automatic collaborative palletising. The technology is not new to the world, but the difference comes with Cama’s native integration: a system that communicates transparently with the case packer.”

In line with Cama Group’s continued focus on machine evolution, the research and development team are currently working on two new functions of the Machine Enhancement Program that are due to be introduced to the market soon.

“We are developing an advanced autonomous mobile robot system that picks pallets from the warehouse and moves them – even hundreds of meters – to the production machines,” says Rocca.

“Edge Computing is the second piece we are implementing. The goal is to transform everything that is done by the machine and for which we have the data into useful knowledge.

“A twofold benefit follows: the customer obtains a stable process and rapid diagnostics, and Cama raises design standards thanks to the efficient use of data to create increasingly high-performing machines.”

These new technologies will be on display at Interpack 2026 in Düsseldorf, Germany, in May 2026. CR

For more information, visit camagroup.com

This article was first published in the November/December 2025 edition of Global Coffee Report. Read more HERE.